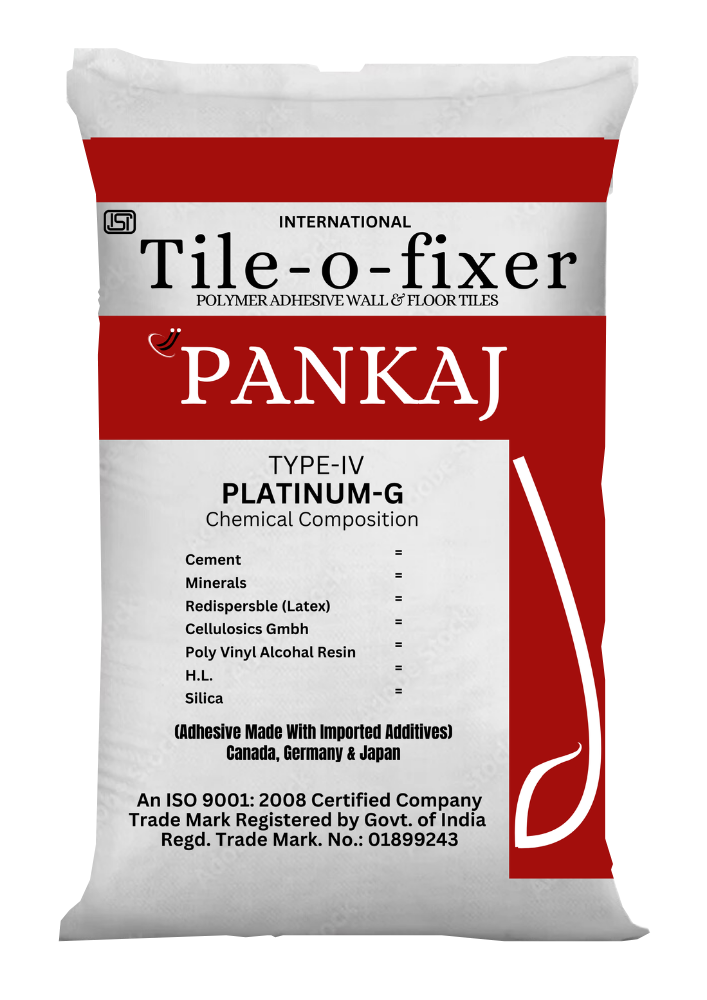

Platinum Adhesive

Platinum Adhesive is a premium polymer-modified adhesive suitable for heavy tiles, stones, granite, and marble. It is ideal for interior and exterior applications and ensures a strong, long-lasting bond on walls and floors. This versatile adhesive performs admirably in harsh conditions, giving outstanding strength and endurance. Its advanced formulation provides dependable performance even in extreme conditions, making it a perfect choice for demanding projects.

Packaging :20kg

Product Description

This adhesive is a premium polymer-modified grey and white cement-based that can be used to install heavy and large format tiles, stones, granite and Marble on walls and floors in both interior and exterior applications. Appropriate for attaching tiles with a bed thickness of up to 6 mm (maximum 12 mm thickness in area of limited extents).

Certification

- ISO 9001:2015 , 14001:2015

- EN 12004:2017, C2TE S1 Type-IV Adhesive

Color:Grey and White

Coverage

Approx. 30-35 sq. ft per 20kg bag with 1/4” x1/4”

(6mmx6mm) square notched trowel for average

Bed of 3mm.

Coverage will vary depending on trowel notch size, type and

Size of tile and substrate smoothness and evenness

PHYSICAL PROPERTIES

| Bed Thickness | 6 mm (can be extended up to 12 mm in area of limited extent) |

| Pot Life | 3 hours |

| Setting Time | 24 hours |

| Temperature Resistance | -5°C to 50°C |

| VOC Content | 2.62 g/L |

Properties as per IS 15477: 2019 @ 27 ± 2°C

| Property: Test Method | Requirement | Typical Values |

| Open Time: EN 1346 | ≥0.50 N/mm² | 0.85 – 1.10 N/mm² |

| Slip Resistance: EN 1308 | ≤0.50 mm | 0.20 – 0.30 mm |

| Tensile Adhesion Strength | ||

Initial: EN 1348 – Clause 8.2 | ≥1.00 N/mm² | 1.50 – 2.00 N/mm² |

After Water Immersion : EN 1348 – Clause 8.3 | ≥1.00 N/mm² | 1.50 – 1.75 N/mm² |

| Heat Ageing: EN 1348 – Clause 8.4 | ≥1.00 N/mm² | 1.15 – 1.40 N/mm² |

| Freeze- Thaw: EN 1348 – Clause 8.5 | ≥1.00 N/mm² | 1.75 – 2.00 N/mm² |

Transverse Deformation: EN12002 | ≥2.5mm <5.00mm | 2.55 mm – 2.65 mm |

| IS Data | ||

| Property : Test method | Requirement | Typical Values |

| Tensile Adhesion | ||

Dry Condition –Annex A (Clause 5.1) | Minimum 1.5 N/mm² | 1.70-1.80 N/mm² |

| Wet Condition – Annex A (Clause 5.1) | Minimum 1.0 N/mm² | 1.50-1.60 N/mm² |

| Shear Adhesion | ||

Dry Condition –Annex B (Clause 5.2) | Minimum 1.5 N/mm² | 1.80-1.90 N/mm² |

Heat Ageing –Annex B (Clause 5.2) | Minimum 1.0 N/mm² | 1.20-1.30 N/mm² |

| Wet Conditions – Annex B (Clause 5.2) | Minimum 1.0 N/mm² | 1.30-1.40 N/mm² |

| Slip Resistance | ||

Slip Resistance –Annex E (Clause 5.5) | ≤0.5 mm | 0.3-0.4 mm |

| Transverse Deformation | ||

Transverse Deformation:(Clause 5.6) | ≥2.5mm<5.00mm | 2.55 mm – 2.65mm |

Features and Benefits

- Premium Polymer Modified Adhesive

- Suitable for Stones, granite, marbles, heavy and large format tiles

- Superior Bond Strength

- Easy Mixing and Application

- Versatile Application

- Reduced Shrinkage

Application Instruction

Substrate Preparation

Make sure the surface is clear of dirt, dust, debris, grease, and other contaminants and that it is dry and clean. To ensure the best adhesion, level the surface and fix any cracks or uneven spots.

Dampen the wall before the application of adhesive.

Clean the back of a tile for any dust or coating.

Mixing

Add Gold Star Magic to clean water in a clean container and mix thoroughly until a lump-free mortar is achieved. Use approximately 5–6 litres of water for a 20 kg bag. You can mix the products by hand or with an electric drill mixer at a low speed (less than 300 rpm). Do not over-mix. Overmixing can introduce air bubbles into the adhesive, which might weaken the bond.

Application

- Spread Adhesive:

Apply the mixed adhesive to the prepared surface using a trowel. Comb through the adhesive with a suitably sized square-toothed notched trowel. Larger tiles require a larger notch to provide sufficient adhesive coverage. Apply a thin layer of adhesive to the back of heavy or large tiles to improve bonding.

- Fixing Tiles:

- Position tiles within the open time, pressing them into place with a twisting and sliding motion to ensure solid bed fixing.

- Use a Pankaj leveller to ensure the tile is correctly positioned.

- Put Pankaj tile spacers between tiles to keep the grout lines straight.

- Clean off any surplus adhesive from the tile face and joints using a damp sponge while the adhesive is still fresh.